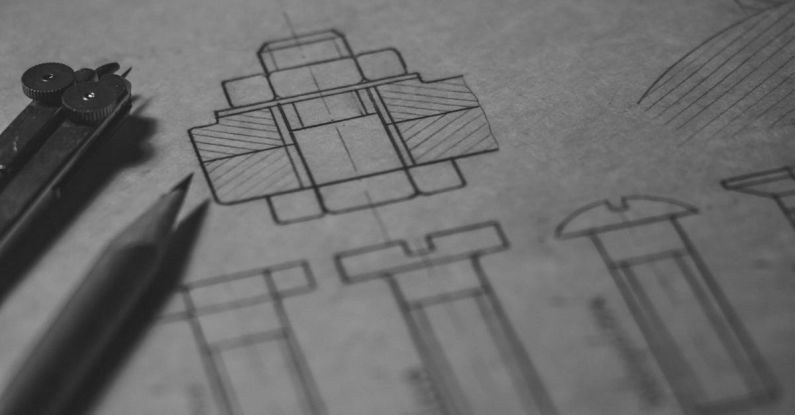

In the ever-evolving realm of mechanical engineering, the advent of computer-aided design (CAD) technology has revolutionized the way custom mechanical components are designed and manufactured. This transformative tool has significantly streamlined the design process, allowing engineers to create intricate and precise components with unprecedented efficiency and accuracy. CAD software has not only accelerated the pace of innovation in the field but has also enhanced the quality and functionality of mechanical components across various industries. Let’s delve into how CAD has reshaped custom mechanical component design and explore the myriad benefits it offers to engineers and manufacturers alike.

Enhanced Precision and Accuracy

One of the most significant advantages of CAD in custom mechanical component design is its ability to deliver unrivaled precision and accuracy. Traditional methods of manual drafting often led to errors and inconsistencies, resulting in costly rework and delays. With CAD software, engineers can create detailed 2D and 3D models with pinpoint accuracy, ensuring that every dimension and specification is meticulously captured. This level of precision not only facilitates seamless collaboration among design teams but also minimizes the margin of error during the manufacturing process, ultimately leading to superior quality components.

Efficient Iteration and Prototyping

CAD technology has revolutionized the iterative design process by allowing engineers to quickly and easily modify designs based on feedback and testing results. With CAD software, designers can make instant revisions to their models, experiment with different configurations, and simulate real-world conditions to evaluate performance. This iterative approach not only accelerates the design cycle but also enables engineers to identify and address potential issues early on, reducing the likelihood of costly design flaws in the final product. Moreover, CAD facilitates rapid prototyping, enabling engineers to create physical models of their designs for further testing and validation, ultimately leading to more robust and reliable mechanical components.

Seamless Integration with Manufacturing Processes

CAD software seamlessly integrates with modern manufacturing processes, enabling engineers to directly translate their digital designs into physical components with minimal manual intervention. By generating detailed manufacturing drawings, Bill of Materials (BOM), and assembly instructions, CAD streamlines the production workflow and ensures consistency and accuracy throughout the manufacturing process. Additionally, CAD software supports a wide range of file formats that can be easily shared with manufacturers, suppliers, and collaborators, fostering greater communication and collaboration across the supply chain. This seamless integration between design and manufacturing not only improves efficiency but also enhances overall product quality and consistency.

Optimized Material Selection and Cost-Efficiency

Another key benefit of CAD in custom mechanical component design is its ability to optimize material selection and reduce manufacturing costs. By simulating various material properties and performance characteristics within the CAD environment, engineers can identify the most suitable materials for a specific application, balancing performance, durability, and cost-effectiveness. Additionally, CAD software enables engineers to optimize component designs for material efficiency, reducing wastage and minimizing production costs. By leveraging CAD tools such as finite element analysis (FEA) and computational fluid dynamics (CFD), engineers can evaluate the structural integrity and performance of their designs under different operating conditions, ensuring that the final components meet the desired specifications while minimizing material and manufacturing expenses.

Enhanced Collaboration and Communication

CAD technology has significantly enhanced collaboration and communication among design teams, stakeholders, and manufacturing partners throughout the product development lifecycle. By creating digital models that can be easily shared, reviewed, and modified in real-time, CAD facilitates seamless collaboration among geographically dispersed teams, enabling faster decision-making and reducing time-to-market. Moreover, CAD software enables engineers to visualize and simulate complex designs, making it easier to communicate design intent and requirements to stakeholders and manufacturing partners. This improved communication not only fosters greater transparency and alignment but also ensures that all parties are working towards a common goal, resulting in better-designed mechanical components that meet the needs and expectations of end-users.

Innovative Design Capabilities

CAD technology has unlocked a new realm of design possibilities for custom mechanical components, enabling engineers to push the boundaries of creativity and innovation. With advanced features such as parametric modeling, generative design, and virtual prototyping, CAD empowers engineers to explore unconventional design concepts, optimize performance, and unleash their creativity without being constrained by traditional design limitations. By leveraging CAD tools to simulate and analyze complex geometries, material properties, and mechanical behaviors, engineers can push the envelope of what is achievable in mechanical component design, leading to groundbreaking innovations and cutting-edge solutions that drive progress and competitiveness in the industry.

Streamlined Documentation and Compliance

CAD technology simplifies the documentation and compliance process for custom mechanical component design by automating the creation of detailed drawings, specifications, and documentation required for regulatory compliance and quality assurance. By generating accurate and comprehensive documentation within the CAD environment, engineers can ensure that their designs adhere to industry standards, regulations, and best practices, mitigating the risk of non-compliance and ensuring product safety and reliability. Additionally, CAD software enables engineers to maintain a centralized repository of design data, revisions, and version history, facilitating traceability and auditability throughout the product lifecycle. This streamlined documentation process not only enhances transparency and accountability but also expedites the approval and certification process, enabling faster time-to-market for custom mechanical components.

Conclusion: Transforming the Future of Mechanical Component Design

In conclusion, CAD technology has revolutionized custom mechanical component design, offering engineers unprecedented precision, efficiency, and innovation capabilities that have fundamentally transformed the way mechanical components are designed, manufactured, and brought to market. By leveraging CAD software to enhance precision and accuracy, streamline iteration and prototyping, optimize material selection and cost-efficiency, facilitate collaboration and communication, drive innovative design capabilities, and streamline documentation and compliance processes, engineers can create superior quality components that meet the evolving demands of the industry. As CAD technology continues to advance and evolve, it will undoubtedly play a pivotal role in shaping the future of mechanical component design, driving innovation, competitiveness, and progress across a wide range of industries.